Materials Matter - Column 4 - Flexible Nano Electronics

- 01 Feb 2020

- Volume 19

- NanoScientific Magazine, Spring 2020

Dr. Rigoberto Advincula, Professor,

Macromolecular Science & Engineering, Case Western Reserve University

The printed flexible electronics market is projected to reach $330 billion by 2027 including different substrates from PET to polyamide to other flexible electronics, RFID tags, electronic paper, flexible solar cell, wearable electronics, sensors and different types of dynamic solid state and display devices, representation in logic, memory circuits, organic light emitting diode displays, and many others. The convergence of function and the ability to fabricate them in a high throughput manner is just going to grow and there's a lot of interest on wearable electronics.

What are flexible electronics?

Wearable electronics represent different types of sensors that go directly onto your skin or implanted, such as sensing mechanism or textile and printed electronics on sportswear or gadgets that can be attached to what you wear every day.

What are the different types of flexible circuit structures?

Flexible circuit structures can be divided into ratio geometries from single sided flex circuits, and then you build on top of this dielectric film features that can represent your circuit, your solid state display, your LCD, and an LED film or LED glass, would be a representation or several flexible automotive lighting composites that would typically be in a fabricator concept device. A double access flex circuit means there’s a pattern on both sides of the substrate, with various methods to produce a finish, multi-material system with multi-layers circuits. A double sided flex circuit can represent flex circuits having two conductor layers, with or without plated two holes, depending on the design requirements, this will then have a fabricated pattern and then a last deposited protective cover layer. The flexible circuits can be stacked to form multilayer flex circuits, building geometry and function in three dimensions. Rigid flex circuits are combinations or hybrid construction of this substrate, as well as metal layer construction on one side or both sides. And perhaps of higher interests in terms of bringing more polymer content into a flex circuit is the use of a polymer thick film as a substrate, a PTF. It simply means you can use polyethylene terephthalate, polyamides, polycarbonates and different types of roll throw plastic substrates that can produce high throughput fabrication methods.

What materials are used in flexible circuits?

Flexible circuit materials are the base material for instance, a polymer film, would be called a laminate that can have a thickness anywhere from a 12 to 125 microns or five mils. This thin film can either be made of PET, polyamide, PEI, polyethyleneimine, or various types of polymers or even silicone polymers to control the chemical resistance and weapon behavior. Another material could be the deposition of a metal. A typical metal foil can be deposited either by printing or by electrolysis deposition methods. This means that you are able to create a pattern based on transfer of the metal material or a reduction of the metal on the surface.

What is the most manufactured device configuration?

PCB is the most manufactured device configuration to integrate capacitors, resistors, and come up with a board that can be used for an instrument or automotive application. There are several hierarchies in this type of manufacturing, which of course can be reduced into a printed or flexible electronics, if carefully designed, so in this level you will be looking at chips, chipsets interconnect scales.

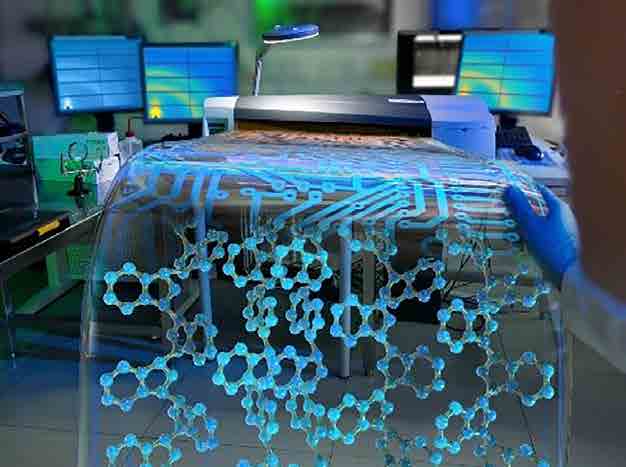

How does nanostructuring and nanomaterials interface with flexible electronics?

Nanostructuring simply means the ability to pick and place design and structure enables self-assembly of these nanomaterials, nanoparticles into a device that can be used either for optimizing an OLED or a sensor device. This can involve integrating an organic polymer material, whether it be the passive or the active component, or an inorganic material, including metal alloys and different types of high conducting materials, this becomes a hybrid system and not a composite. But putting this or integrating these all together requires an ability to synthesize, design and engineer this then on a nanoscale, positioning the patterning using a high vacuum environments ability to nucleate formation of these metals in a block copolymer composition or ability to control their self-assembly. Organic polymer materials give you a different hierarchy of ordering or supra molecular assembly. The orientation or even liquid crystal in behavior of different organic materials can be controlled.

This column is an excerpt from a webinar led by Dr. Advincula.

The webinar also describes in depth research being done in Dr. Advincula’s lab on future flexible electronics. To listen to the entire webinar, go to: https://youtu.be/978mqMWZ47Y