Park SmartLitho – A Novel Approach for Nanopatterning Using AFM Lithography

- 30 Sep 2020

- Volume 20

- NANOscientific Magazine, Summer 2020

Research Application Technology Center, Park Systems Corp.

Introduction

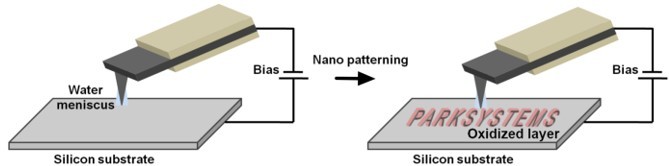

Since the invention of atomic force microscopy (AFM) [1], it has found widespread application in non-destructive sample surface imaging and significant interest in its electrical, magnetic and mechanical properties. However, in addition to those, AFM offers vast potential for local surface modification and patterning, using either excessive cantilever loading force resulting in mechanical scratching, ferroelectric switching or by oxidizing the surface via the application of AFM tip bias. Local oxidation, also known as ‘bias mode AFM nanolithography,’ has been widely used in the customization of nanoscale conducting or semiconducting surface patterning [2, 3]. Bias mode AFM nanolithography offers many advantages for customized patterning: it circumvents the diffraction limit present in optical lithography methods, it does not require optical masks and its procedure is straight forward. By applying a voltage bias between a conductive AFM tip and a substrate, the tip-sample contact region forms an oxidized layer (Figure 1). Nanopattern control by oxidation occurs by manipulating experimental parameters, including the applied AFM tip bias, the tip material/geometry, scan speed and humidity.

In this application note, we present nanopatterning via oxide growth on a bare silicon wafer [4] using bias mode AFM nanolithography with Park SmartLitho, the new nanolithography software developed by Park Systems [5]. Furthermore, we demonstrate the capabilities of Park SmartLitho for lithography on ferroelectric samples by patterning local domains of a PZT (lead zirconium titanate) film on silicon wafers [6]. Using Park SmartLitho, we fabricated complex structures with detailed and elaborate features, via both oxidation and ferroelectric domain switching. Finally, we propose optimized process parameters for successful nanopatterning. The software is ideally suited for novel device surface structure development based on nanolithography and for investigations into ever decreasing feature sizes and line spacings for advanced nanoelectronics.

Figure 1. Schematic representation of bias-assisted AFM nanolithography via local surface oxidation. Patterns are created on the surface by oxidation upon bias application between tip and sample.

Materials and Methods

A bare silicon wafer and a PZT film on a silicon wafer were used to demonstrate nanopatterning via oxidation and ferroelectric domain switching, respectively. The root mean square roughness (Rq) for the bare silicon wafer was > 1 nm so that the height contrast between the oxidized layer and the substrate could be identified. We used a CDT-NCHR cantilever with a nominal spring constant of 80 N/m and a resonance frequency of 400 kHz for oxidation nanopatterning. The CDT-NCHR tip contains a conductive diamond coating (< 10 kOhm at the platinum surface) and the tip curvature radius was 100 nm ~ 200 nm. The tip radius of the CDT-NCHR was slightly larger than tips with other conductive metal coatings; however, diamond coated tips show improved operational stability and higher sensitivity. For nanopatterning via ferroelectric domain switching on a PZT, we used a PPP-EFM cantilever with a nominal spring constant of k = 2.8 N/m and a resonance frequency of 75 kHz. The PPP-EFM tip has a platinum-iridium coating and a radius of approximately 25 nm. Since ferroelectric domain switching on PZT does not require a high loading force between the AFM tip and the sample surface, a soft conductive cantilever was used. The detailed scan parameters are found in Table 1.

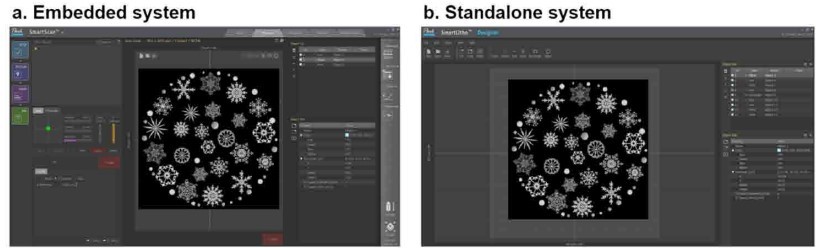

All measurements were conducted on a Park NX10 AFM system utilizing Park SmartLitho, the new AFM nanolithography software from Park Systems. Park SmartLitho combines a variety of nanolithography modes, including constant Z scanner mode, constant force mode, bias (and other) modes with a user-friendly graphic editor. The user can access many template types for customized nanopatterning such as bitmap images, polygons, polylines and polydots. Park SmartLitho is available either as a stand-alone version or embedded in the Park SmartScan™ operating software (Figure 2). The stand-alone and embedded versions offer the same functions, like drawing file creation as well as bitmap or pattern editing, and can operate the user’s chosen/preferred nanolithography mode.

Table 1. AFM nanolithography parameters

Figure 2. Captured images of Park SmartLitho software, (a) embedded in Park SmartScan imaging software and (b) the stand-alone version.

Results and discussion

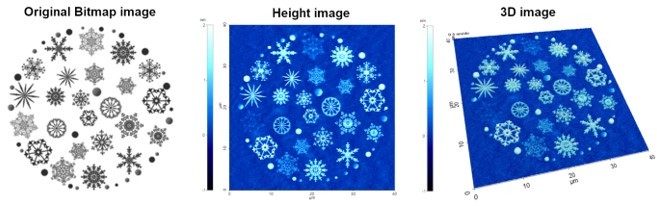

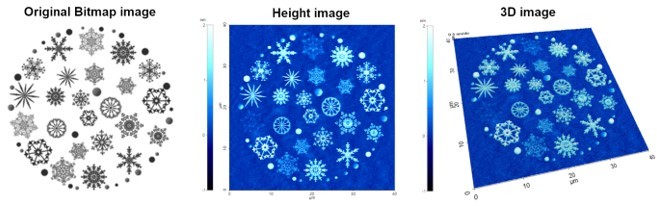

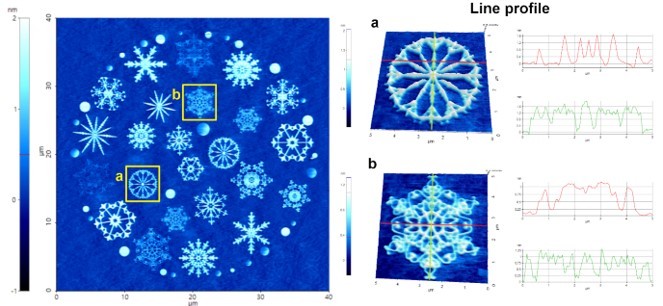

Figure 3 shows the original bitmap image used as the nanopatterning template as well as the height and corresponding 3D images of the sample surface after bias mode AFM nanolithography. The nanopattern on the surface of the bare silicon wafer resembled the template of the Christmas ball closely. The pattern was generated using bias assisted silicon oxidation by applying a sufficiently high voltage between the tip and sample. The oxide layer thickness was controlled by the applied bias magnitude and environmental humidity. The oxide layer thickness was directly proportional to the applied tip bias. Furthermore, oxidation required a water meniscus at the AFM tip end that was influenced by environmental humidity [7]. Therefore, the measurement was conducted from a 0 V ~ 10 V tip bias under high humidity conditions (> 60%). The oxide nanopattern featured heights that ranged from 0.8 nm ~ 1.5 nm. Figure 4 shows two of the constituent structures (5μm×5 μm) with their corresponding 3D images and line profile information. From these line profiles, we confirmed structure heights of approximately 1 nm. The distinct height image contrast after nanolithography illustrated the successful and high-resolution nanopatterning available by bias assisted oxidation using the new Park SmartLitho software from Park Systems.

Figure 3. Original bitmap image used as the template (left), AFM height image after bias assisted AFM nanolithography (center) and corresponding 3D image of the sample surface (right). The nanopatterning was generated by surface oxidation.

Figure 4. AFM height images after nanolithography and line profile analysis on two of the constituent structures. AFM line profiles in a and b show the ~1 nm height of the oxide layer from the substrate.

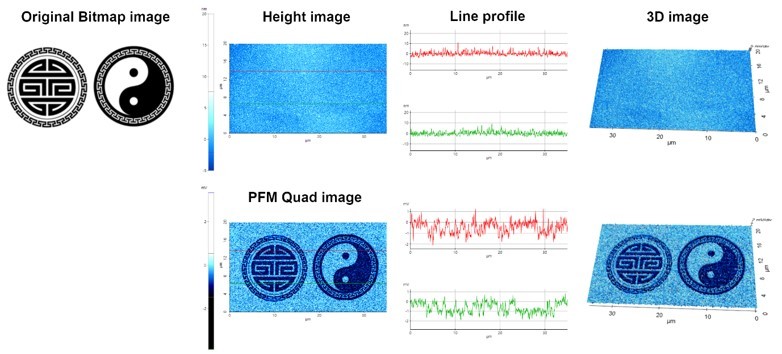

Figure 5 shows height and piezoelectric force microscopy (PFM) quad images, their line profile information and 3D images after lithography. Ferroelectric domains in PZT can be switched by applying different biases between the tip and sample. We performed both AFM non-contact imaging for height information and PFM imaging for PFM quad information after bias mode AFM nanolithography. As shown in both, the height images were flat surfaces without a pattern. However, the structure resolved in the PFM quad strongly resembled the original traditional Korean pattern template, illustrating successful ferroelectric domain switching. While nanopatterning by oxidation requires humidity control for high-quality nanolithography, nanopatterning via ferroelectric switching requires slow scan speeds and lower loading force scanning to avoid sample damage due to contact mode.

Figure 5. Original bitmap images used as templates (left), AFM height and PFM quad images after ferroelectric switching in AFM nanolithography bias mode, line profile analysis (center) and the corresponding 3D images (right). The nanopattern on PZT was generated by ferroelectric domain switching.

Conclusion

In this application note, we demonstrate the nanopatterning via oxide growth on a bare silicon wafer using bias mode AFM nanolithography with Park SmartLitho, a novel nanolithography software from Park Systems on a Park NX10 AFM system. We successfully showed that using Park SmartLitho, a bias assisted nanopatterning of complicated structures can be readily done by locally oxidizing the surface of a silicon wafer and switching ferroelectric domains of a PZT film. Furthermore, we proposed optimized parameters including humidity values, a tip bias range, scan rate and suitable cantilevers to generate accurate and distinct nanoscale oxide patterns on a silicon substrate as well as ferroelectric domain patterns on PZT. This study demonstrates that nanopatterning by AFM nanolithography, in particular oxidation patterning on silicon substrates and Park SmartLitho, offers significant potential for customized nanosensor surface modification as well as nanodevices for semiconductor research and industry.

References

1. Binnig, G., Quate, C. F., & Gerber, C., Atomic force microscope. Physical review letters, 56 (9) (1986) 930.

2. Minne, S. C., Flueckiger, P., Soh, H. T., & Quate, C. F., Atomic force microscope lithography using amorphous silicon as a resist and advances in parallel operation. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures Processing, Measurement, and Phenomena, 13 (3) (1995) 1380-1385.

3. Garcia, R., Martinez, R. V., & Martinez, J., Nano-chemistry and scanning probe nanolithographies. Chemical Society Reviews, 35 (1) (2006) 29-38.

4. Garcı́a, R., Calleja, M., & Pérez-Murano, F., Local oxidation of silicon surfaces by dynamic force microscopy: Nanofabrication and water bridge formation. Applied Physics Letters, 72 (18) (1998) 2295-2297.

5. Advanced Vector Nanolithography Using Closed Loop Scan System (2010, Online Article). Retrieved from:https://parksystems.com/park-spm-modes/97-mechanical-properties/251-nanolithograpy

6. Li, D., & Bonnell, D. A., Ferroelectric lithography. Ceramics International, 34 (1) (2008) 157-164.

7. Abdullah, A. M., Hutagalung, S. D., & Lockman, Z., Influence of room humidity on the formation of nanoscale silicon oxide patterned by AFM lithography. International Journal of Nanoscience, 9 (04) (2010) 251-255.