Evaluation of Local Mechanical and Chemical Properties via AFM as a Tool for Understanding the Formation Mechanism of Pulsed UV LaserNanoinduced Patterns

- 13 Jan 2022

- Volume 23

- NANOscientific Magazine, Park Systems Special Edition

Iuliana Stoica 1*, Elena-Luiza Epure 2, Catalin-Paul Constantin 1, Mariana-Dana Damaceanu 1,

Elena-Laura Ursu 1, Ilarion Mihaila 3 and Ion Sava 1

Abstract

Aromatic polyimides containing side azo-naphthalene groups have been investigated regarding their capacity of generating surface relief gratings (SRGs) under pulsed UV laser irradiation through phase masks, using different fluencies and pulse numbers. The process of the material photo- fluidization and the supramolecular re-organization of the surface were investigated using atomic force microscopy (AFM). At first, an AFM nanoscale topographical analysis of the induced SRGs was performed in terms of morphology and tridimensional amplitude, spatial, hybrid, and functional parameters. Afterward, a nanomechanical characterization of SRGs using an advanced method, namely, AFM PinPoint mode, was performed, where the quantitative nanomechanical properties (i.e., modulus, adhesion, deformation) of the nanostructured azo-polyimide surfaces were acquired with a highly correlated topographic registration. This method proved to be very effective in understanding the formation mechanism of the surface modulations during pulsed UV laser irradiation. Additionally, to AFM investigations, confocal Raman measurements and molecular simulations were performed to provide information about structured azo-polyimide chemical composition and macromolecular conformation induced by laser irradiation.

Introduction

Polyimides (PIs) represent an important class of high-performance polymers that are exploited in a variety of applications due to their excellent physicochemical properties such as optical and thermal stability in combination with high glass transition temperature, low susceptibility to laser damage, and low dielectric constant value [1,2]. Moreover, polyimides have been investigated as potential materials in the fields of optoelectronics and photonics [3]. Particularly interesting are polyimides containing azobenzene units, which have already been investigated for photoinduced alignment in liquid crystal dis- play [4], as photomechanical response materials [5], and for holographic diffraction grating recording [6–11]. This study focuses on the investigation of a newly synthesized aromatic polyimide containing azo-naphthalene side groups with the aim to evaluate the local morphological, mechanical, and chemical properties via atomic force microscopy, especially in PinPoint mode, and confocal Raman spectroscopy. It is meant to provide a deep understanding of the formation mechanism of SRGs induced by pulsed UV laser on these azopolyimide films, through phase masks, using different fluencies and number of pulses. Moreover, this article attempts to correlate the macroscale behavior of this azo-naphthalene-based polyimide during photoisomerization with the one from the atomic level simulating certain polymeric systems with a different content of the cis isomer.

Materials, Methods and Measurements

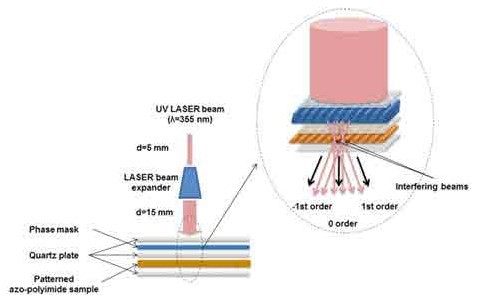

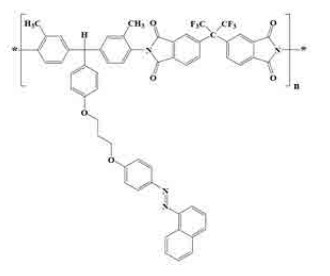

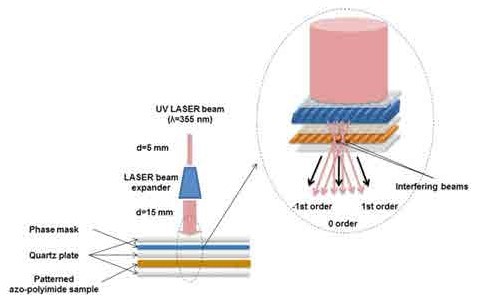

An aromatic diamine containing the azo group (-N=N-) pendent to the triphenylmethane core was synthesized by the Williamson reaction of 4-[bis-(4-amino3-methyl- phenyl)-methyl]-phenol with 3-[4-naphthalen-1-ylazo)-phenoxy]- bromopropane. The azopolyimide has been synthesized by the polycondensation reaction of 6FDA with the above In order to induce micro/nano structuration on the azo-polyimide surface, the setting presented in Figure 2 was used. Nanomechanical measurements were made on a Park NX10 Atomic Force Microscope (Park Systems Corp., Suwon, Korea), using PinPoint Nanomechanical mode, which allowed us to obtain sample’s stiffness mapping through force–distance curves acquired at each pixel over the entire scanning area (of 1 × 5 µm2 in our case). Thus, the quantitative nanomechanical properties (i.e., modulus, adhesion, deformation) of the nanostructured azo-polyimide surfaces were acquired with highly correlated topographic registration. In order to provide the most accurate mechanical properties data, we carefully selected the Force Modulation Mode - Reflex Coating (FMR) probe (Park Systems Corp., Suwon, Korea) with a force constant of 2.8 N/m and resonance frequency of 75 kHz according to the relative stiffness of their cantilever when compared to that of the sample, so that it can offer immediate response to any changes on the surface’s material properties. The scanning frequency was 0.5 Hz, and the scanning speed was 5.0 µm/s.

Figure 1. Chemical structure of the novel azonaphthalene-based polyimide, AzoPI, used in this study.

Results and Discussion

Nanomechanical Characterization Using AFM PinPoint Mode

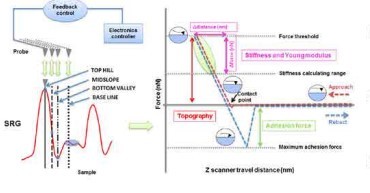

PinPoint Nanomechanical mode was designed to prevent positional errors by simultaneously acquiring accurate height and force–distance information in each of the 256 × 256 pixels in the whole scanning area, thus preventing the occurrence of the artifacts and positional errors in force–distance spectroscopy and topographical data. In Figure 5 and Appendix B, we present the working mechanism of PinPoint Nanomechanical mode, describing the generation of the map of the sample’s stiffness/elasticity and deformation depth from the surface concomitantly obtained through the adhesion force map with the topographic sample information [59–64].

Figure 2. Pulsed laser irradiation through a phase mask setting, with a detail on the formation of interference image on the azo-naphthalene-based polyimide surface

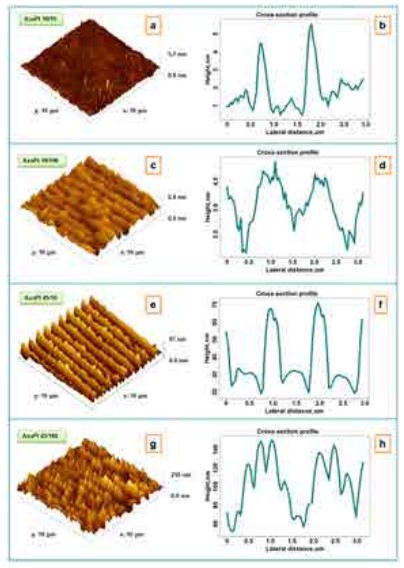

Figure 3. Height 3D atomic force microscopy (AFM) images and corresponding cross-section profiles for azo-polyimide irradiated using different laser energy density/number of pulses of irradiation: 10 mJ/cm2 /10 pulses (a,b), 10 mJ/cm2 /100 pulses (c,d), 45 mJ/cm2 /10 pulses (e,f), 45 mJ/cm2 /100 pulses (g,h)

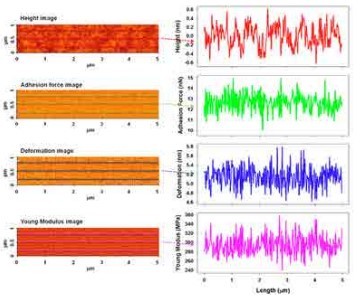

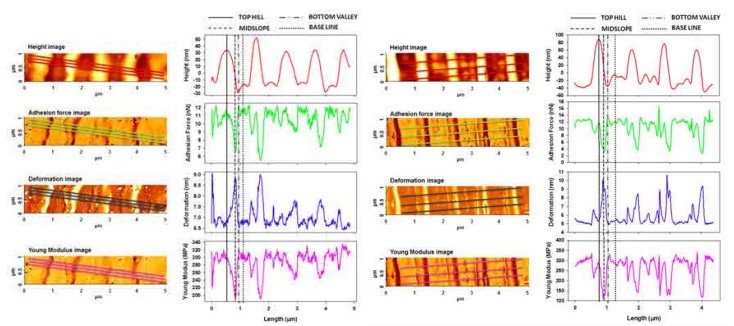

Figures 6–8 show the PinPoint combined height, adhesion force, deformation, and Young’s modulus AFM images and corresponding cross-section profiles in the case of pristine (Figure 6) and irradiated azo-polyimide with a laser energy density of 45 mJ/cm2 and either 10 pulses (Figure 7) or 100 pulses (Figure 8). The last two samples were selected for this kind of measurement because the generated modulations were very well defined, facilitating the investigations in different positions of interest (on the top hills, middle slopes, base, and bottom valleys of the SRG, as indicated in Figure 5).

Figure 5. Working mechanism of PinPoint Nanomechanical mode: the tip of the cantilever is moved at each of 256 × 256 points along a sample’s surface, and the feedback system controls the approach and retraction of a probe, allowing the acquirer of both surface topography and force–distance curves, and further to extract the mechanical property data

Figure 6. AFM PinPoint combined height, adhesion force, deformation, and Young’s modulus images and representative cross-section profiles taken along the middle line obtained for pristine azo-polyimide.

Conclusions

The aim of this study was to provide new insights regarding the formation mechanism of pulsed UV laser-nano induced patterns on azo-naphthalenebased polyimide films by evaluating the morphological, statistical, local mechanical, and chemical properties via AFM, in correlation with the molecular modeling. The quantitative nanomechanical properties (Young’s modulus, adhesion, deformation) of SRGs using the AFM PinPoint method were acquired with highly correlated topographic registration. The experimental evaluations highlighted different values of nanomechanical parameters obtained in different regions of the patterned relief. These were induced by re-organization of the matter by azo-naphthalene dipoles orientation and material photofluidization induced by repeated trans–cis isomerization of the azo-segments. Attempts have been made to explain experimental phenomena by molecular modeling.

Figure 7. AFM PinPoint combined height, adhesion force, deformation, and Young’s modulus AFM images and corresponding cross-section profiles mediated from the presented three lines obtained for azo-polyimide irradiated with a laser energy density of 45 mJ/cm2 and 10 pulses. Figure 8. AFM PinPoint combined height, adhesion force, deformation, and Young’s modulus images and corresponding cross-section profiles mediated from the presented three lines obtained for azo-polyimide irradiated with a laser energy density of 45 mJ/cm2 and 100 pulses.

The photoisomerization phenomenon was studied using three systems in which the content of cis isomers was gradually increased. Although the variations of the statistical and dynamic parameters such as the fractional free volume, end to end distance, mean square displacement, or dipole moment were small from one system to another, their evolution followed the same behavior as that observed at the macroscale during the photo-isomerization process. It was found that polymers with 50% azo groups in cis had either a maximum or a minimum peak of the calculated parameters. The low mobility of the chains with a maximum content in the cis isomer could explain the phenomenon of azopolymer hardening due to the photoisomerization process. In addition, confocal Raman measurements evidenced no significant spectral changes, except for the slight increase of the absorption band due to the cis isomer evolution, demonstrating their origin in the polymer conformations before and after irradiation rather than in the polyimide chemical modifications.

To download the complete original article, please go to https://bit.ly/3oQLtZ0 This article originally appeared on Nanomaterials 2021, and condensed by NanoScientific under Creative Commons Attribution License