Park AFM Scholarship Awards - Akshay Gowda

- 07 Jan 2019

- Volume 15

- NanoScientific Magazine, Winter 2019

A Graduate Student Working With Dr. S.V. Babu,

Distinguished University Professor,

Clarkson University Receives The

Park Afm Scholarship Award

Title of Research Paper:

Post-CMP Cleaning of Ceria Particles from Silicon Dioxide and Nitride Wafers for Advanced Technology Nodes

Abstract:

Advanced device manufacturing requires stringent process conditions to prevent defects that can lead to device failure and reliability issues. In particular, defects such as residual particles, foreign materials, scratches, etc. should be removed from the wafer surface aft er chemical mechanical planarization (CMP).

How do you use AFM in your research?

Chemical mechanical planarization (CMP) is one of the most crucial steps in the manufacturing of integrated circuits (ICs). In a typical CMP process, a wafer is pressed against the polishing pad fixed to a rotating platen and the chemical slurry (consisting of abrasive particles and necessary chemical additives) is supplied on to the pad. The wafer is polished by the combination of chemical and mechanical forces. CMP inevitably introduces surface defects and contaminants due to the presence of chemical additives and abrasive particles in the slurry used to planarize wafer surfaces. Surface particles are one of the major defects induced by CMP. If not removed, they can cause short or open circuits and aff ect the final device performance and reliability. Therefore, cleaning such particlulate defects on wafer surfaces postCMP is critical for successful manufacturing of ICs to improve productivity. Billion or so active transistors in each IC is electrically isolated using shallow trench isolation (STI) CMP. Ceria particle-based slurries are used to polish STI structures. Due to high chemical aff inity of ceria particles to silicon dioxide surfaces, STI CMP leads to particle contamination making post-CMP cleaning challenging as ceria particles adhere very strongly to STI wafers during polishing. In our research, we are developing cleaning chemistries than can remove ceria particles from silicon dioxide wafers. The particles on silicon dioxide wafer surfaces before and aft er cleaning are imaged using atomic force microscopy (AFM) and counted. Subsequently, cleaning eff iciency is calculated to evaluate the eff ectiveness of the developed cleaning chemistry.

“Particles On Wafer Surfaces Can Be Imaged Easily Using Afm As Compared To

Other Microscopic Techniques. Some Of The Benefits Of Using Afm Over Other Microscopic Techniques Are As Follows: Even Very Small Nanoparticles (<20nm) Can Be Imaged Easily Using Afm; Imaging Wafers Using Afm Does Not Require Any Sample Preparation; Afm Is A Simple, Flexible, And Cost Effective Technique And The Image Quality Is Excellent With Good Reproducabilty; Afm Images Can Be Further Processed To Obtain More Information Like Size, Surface Quality, Etc.”

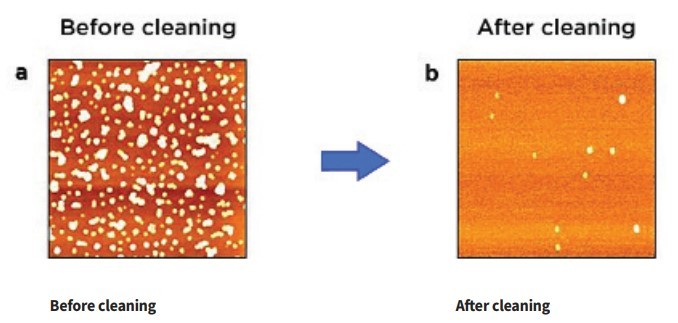

Figure 1. AFM image of silicon dioxide wafer surface (a) contaminated with ~30 nm (mean diameter) ceria particles and (b) cleaned with a cleaning solution In this case, the number of particles before and after cleaning is 290 and 12 respectively and the corresponding cleaning efficiency is 96%.

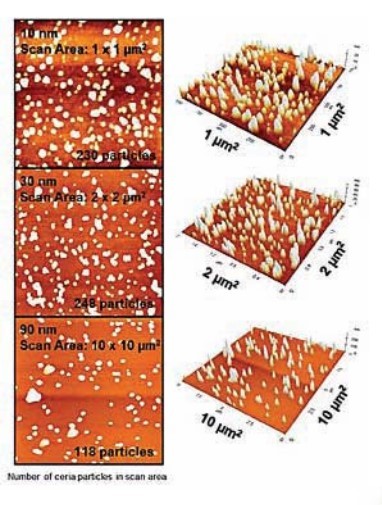

Figure 2. Topographic images of adsorbed ceria particles on silicon dioxide wafer surfaces in scan areas of 1 × 1 µm2 (for ~10 nm ceria particles), 2 × 2 µm2 (for ~30 nm ceria particles) and 10 × 10 µm2 (for ~90 nm ceria particles). Different scan areas were chosen for different sized particles to obtain adequate number of particles in AFM images.

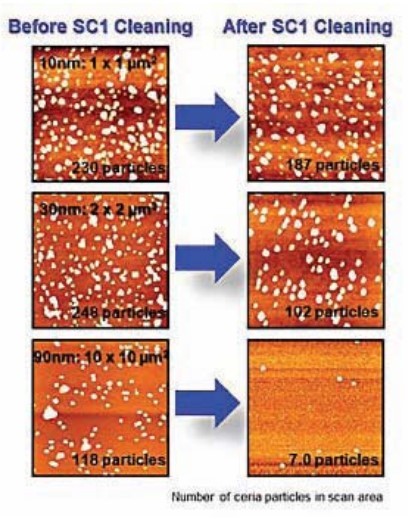

Figure 3. AFM images of adsorbed ceria particles on silicon dioxide wafer surfaces and the corresponding number of particles before and after cleaning with standard clean 1 (SC1) solution in scan areas of 1 × 1 µm2 (10 nm-ceria), 2 × 2 µm2 (30 nm-ceria), and 10 × 10 µm2 (90 nm-ceria).