The Nexus between Nanotechnology and Society 5.0

- 02 Jun 2023

- Volume 23

- NANOscientific Magazine, Park Systems Special Edition

President, Dr. Leandro Berti

President of BrasilNano – The Brazilian Nanotechnology Association

and CEO of FIBER INOVA – a strategic innovation consultancy company.

Leandro Berti has over 20 years of experience in Nanotechnology and Advanced Technologies and current is the CEO of FIBER INOVA (www.leandroberti. com.br) and President of BrazilNano – The Brazilian Nanotechnology Association. Berti studied Computer Engineering at the University of Itajai Valey (UNIVALI), earned his PhD in Nanotechnology at the University of Sheffield (UK) and his Postdoctorate in Nanobiotechnology at the Federal University of Santa Catarina (UFSC – BR). Creator and Coordinator of the SUPERHUB of Nanotechnology of Paraná, Manager of Graphene Projects in the Automotive Industry at SAE Brazil. He served as Head of Key Enabling Technologies and Head of Strategic Technologies at the Ministry of Science, Technology, Innovation in Brazil (MCTI), responsible for national public policy, strategy for Nanotechnology, Photonics, Advanced Materials and Industry 4.0. Created the National Action Plan for Key Enabling Technologies; Included Nanotechnology in the Route 2030 program, created the Legal Framework for Nanotechnology and Advanced Materials. He served as a member of the Science and Technology Committee of the National Council of Science and Technology, BRICS WG Photonics National Representative, OECD BNCT - Nanotechnology National Representative, Brazil-Canada Joint Committee for Cooperation on Science, Technology and Innovation; Director of the Brazilian-Argentine Center for Nanotechnology, President of the Brazilian-Chinese Center for Nanotechnology. He also served as the Executive Secretary of API. nano at CERTI Foundation. Author of the first book on regulation with Nano safety in Brazil.

Image created by Leandro Antunes Berti (refences from LuxResarch, product.statnano.com, http://www.oecd.org/sti/nanotechnology-indicators.htm).

As the Head of Key Enabling Technology at the Ministry of Science and Technology in Brazil and under his leadership released the first National Action Plans for Key Enabling Technologies , currently in use, whose main focus is to promote integration between academia and industry by means of Technology-push and Demand-pull. On the Technologicalpush side are the National Systems and Programs, the Public and Private Laboratories, the Research Technology and Innovation Organizations (RTOs) and the Higher Education aligned with the Action Fronts in Nanotechnology, Photonics, Advanced Materials and Technologies for Industry 4.0 (4IR). On the other side is the Demand-pull that connects with the action fronts through attraction elements, which are concrete actions for the construction of consistent and robust bridges for science and technology to reach the market through innovation. He also pioneered the inclusion of Society 5.0 as one of the main policies for the success of Industry 4.0 in Brazil.

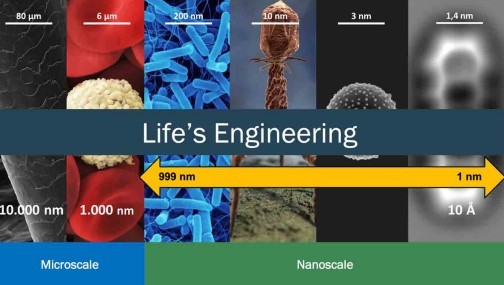

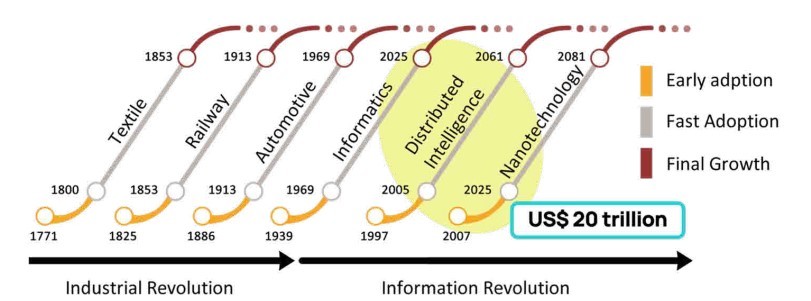

The main form of molecular assembly at the nanoscale is self-assembly, a natural process where separate or linked components spontaneously form larger structures. The material that makes up cell structures, such as proteins, enzymes and even DNA itself, are nano in size. Understanding and applying this vision that values the natural has always benefited humanity. The new properties of nanomaterials discovered from the understanding nature, revolutionize not only products, but also capital goods – production machines – and the provision of services, with innovations that until now were unimaginable. According to the Kondratiev cycle, the new wave of economic growth is Nanotechnology, and in recent years (2020) has reached US$ 20 trillion, mainly to the immense increase of products to fight the coronavirus pandemic. An example, is the graphene market, which has an estimated value of US$ 100 to 20 thousand for each kilogram of material, could reach US$ 876 million in 2027 with a CAGR of 41% (2020 – 2027), with applications in electric batteries, tires, conductive paints, flexible electronics, smart concrete, among others. The pervasive nature of Nanotechnology allows it to reach even larger markets such as the Internet of Things (IoT). The IoT international road mapping report, from the Smart Action – Innovating beyond IoT , presents a series of advantages and improvements that Nanotechnology adds to IoT solutions. The report also emphasizes that the priority themes are energy storage and generation, nanoelectronics, nanosensors, nanomaterials and even nanomachines, nanonetworks and the Internet of Nanothings (IoNT). IoT is one of the tools of Industry 4.0 that allows the integration of new nanosensors connected in a network to, for example, control the forecast of production and losses in real time, a market worth billions of dollars. The industry 4.0, has several names and representations, in the European Community it is known as Industrial Renaissance (Industrial Renaissance), in Germany as Industry 4.0, in the US as Advanced Manufacturing, but in fact they seek the growth and post-crisis modernization of the globalized world. It is characterized by the integration and remote control of production, from sensors, equipment and machines connected in a network (automation and systems digitization associated with cyber physical systems). Is a philosophy, a cultural change in essence, it is not only related to the production of electronics, but also to Intelligent Production, and with important application in the traditional sector of agriculture, health and goes far beyond what is recommended in several reports, as its greatest impact will be on world geopolitics. The Digital Transformation (DX) is a means to achieve the industry 4.0. Digital Transformation without Nanotechnology and other strategic technologies is not feasible. Just relying on IT to implement the Digital Transformation is a simplification and might lead us to unsustainable path. It’s important to understand that the path to Industry 4.0 is in the convergence of many technologies that are complementary to each other. However, we need to solve this puzzle placing and connecting the outputs of those technologies to create the best possible path to achieve Industry 4.0. As an example of applying the concept of Industry 4.0 in agriculture, is the integration of various nanosensors and IoT equipment to monitor the soil, the climate, the position of the soy pod or apple tree, to ensure the production of the best grain from soy or the best apple that local conditions allow. All this connected in a network, with production and losses forecast in real time, called Agriculture 4.0. In healthcare, an application example is the remote control of medical equipment that will facilitate the monitoring of patients, reducing the response time for emergencies. We recently saw a soaring increase of technologies derived from mRNA, in special the new corona virus vaccine technology. In fact, this new form of delivering the agent to fight the disease is way beyond vaccines, it’s a comprehensive platform to create a better vehicle to delivery drugs to the right target. That has open up a new era for pharmaceutical companies, called Health 4.0. Another important fact that is beyond IoT, is that Industry 4.0 requires machinery that is resilient, durable and robust enough to be able to complete the new worldwide production journey, which will be high volume, high frequency, high speed, highly customized and unsupervised. One of the main candidates to enable Industry 4.0 is Graphene, a 2D material type, with twodimensional layers, which has fantastic properties, such as: ballistic conductivity (100x Copper), accelerated cooling (500 W/mK), mechanical strength (100x Steel), ultraflexible (< 200 MPa ) and impervious to fluids (omniphobic). Therefore, the machinery must support production cycles much longer, faster and more demanding than those currently practiced, and Graphene is here to help. If we look closely, every time the humanity discovers a new phenomenon, we are enticed to create new technology. For example, when we discover fire, the human took ages to control it and benefit from it, in a Hunting Society. Many more years and we develop irrigation techniques and start establishing settlements, but even in that Agrarian Society we had no idea on how to use the fire, unless for cooking raw food. Humans had evolved very slowly until they starting trading goods across the globe, and with the advent of Coffee Shops (1652), the population that mostly drank fermented beverages and stayed in a light drunk state, are now drinking a reinvigorating beverage such as coffee and tea. That made us more awake and new ideas started to flow, and one the ideas that flourished the most was the Steam Machine, a machine powered by fire that produced steam. Now the humans could create the beginnings of automation, and gave rise to the Industrial (Revolution) Society. From that point onwards we have seen an enormous amount of technology been created and society evolve a thousand times faster than before. The lesson here is that society had to evolve beyond the control of fire to be able to fully benefit from it. That has been always true and for us to fully benefit from Industry 4.0 we need be in the Society 5.0.

Digital Transformation (DX), image created by Leandro Antunes Berti.

“For society to fully benefit from Industry 4.0 we need be in the Society 5.0”

The Japanese government together with the Federation of Industries of Japan (Keidanren) identified that society will advance towards becoming a super-intelligent society (Society 5.0) , demonstrating an environment increasingly connected with harmonious coexistence with robots and autonomous machines, the seamlessly integration of the physical world and the digital world – phygital (physical-digital). This social change is need to address the issues of increasing population age, low birth rates, limited electricity, natural disasters, security and social inequality. The Society 5.0 concept goes further and has the main objective of converging all existing technologies to improve the quality of life in general. The advent and access to new technologies allow the emergence of new production chains, better adapted to national and global reality. Unveiling this advanced society with an elderly majority requires not only the re-qualification of experienced labor (healthy aging), but also a more qualified workforce. Workers versed in the most diverse technological advances, more productive, and who know how to live with sudden changes, increasingly present in everyday life. Failure to meet this need can cause a destabilization of social security, leading to the loss of at least a generation of workers. Key components of today's society such as health, recreation, work, consumption, mobility, education and security will be profoundly impacted. This new society that is the result of the revolution in Technologies for Advanced Manufacturing will be more demanding, as the customization of products and services will reach a very high level. However, to obtain products and services that aim to increase the quality of life, reduce social inequalities and increase awareness of environmental preservation, technological solutions must overcome five obstacles: 1) State Bureaucracy Wall: formulation of national strategies, through real integration and effective dialogue between ministries and government agencies; 2) The legal system Wall: reduction of interventionism and approval of laws that facilitate and encourage innovation; 3) Technology Wal: promote technologies related to cyber security, Artificial Intelligence and robotics; and the guarantee of a minimum budget for R&D+I and technological development; 4) Human resources Wall: promote an educational reform that promotes the teaching of information technologies and emerging technologies, that encourages creativity and creates highly skilled professionals); and 5) Social acceptance Wall: building a "social consensus" through dialogue with society that discusses everything from the relationships between people and machines to the meanings of "happiness" and "personal satisfaction". Conquering these obstacles will enable society to overcome not only the challenges of innovation and technological advancement, but also to achieve UN’s Sustainable Development Goals (SDGs). In particular, in the social aspect, Graphene meets at least 11 of the 17 SDGs and its versatility and breadth of applications allows Graphene to be one of the main materials for a sustainable future . This leads us to understand that Graphene is an integral part of the generation of a new society centered on the generation of value, sustainable in the four axes: political, social, economic and environmental, is phygital and strengthens the ESG adoption. That is the Nexus between Nanotechnology and Society 5.0.

Image created by Leandro Antunes Berti

References

1 KET - Brazilian National Plan https://antigo.mctic.gov.br/mctic/ opencms/salaImprensa/noticias/ arquivos/2018/10/MCTIC_lanca_plano_ de_acao_para_o_desenvolvimento_da_ nanotecnologia_e_da_industria_40_ no_Brasil.html 2 IoT International Roadmapping, Smart Action (http://cordis.europa.eu/docs/ projects/cnect/4/609024/080/ deliverables/001-20150630udesmartac tionIoTInternationalRoadmapd22puAr es20152863783.pdf) 3 Keidanren – Federação das Indústrias do Japão, (http://www.keidanren.or.jp) 4 Graphene Flagship – https://grapheneflagship.eu/graphene/news/grapheneis-sustainability/