“Materials Matter” Column 5 - 4D Printing

- 30 Sep 2020

- Volume 20

- NANOscientific Magazine, Summer 2020

Dr. Rigoberto Advincula, Professor, Macromolecular Science & Engineering, Case Western Reserve University

Where does the future of 3D printing go?

What applications are there in industry, research, biomedical engineering, and even outer space? Common 3D printing methods such as FDM (Fused Deposition Modeling), SLA (Serial Lithographic Apparatus), or SLS (Selective Laser Sintering) are familiar by now and many scientists are actively using them. In order to have as far and as wide an application of 3D printing for industrial and research needs, it is important that more materials become available and more types of new applications are envisioned. This includes adding the fourth dimension of stimuli responses to 3D printed materials.

What are stimuli responsive materials?

Stimuli responsive materials or polymers are what can be found in micelles, nanogels, and oil and water interfaces – that have the ability to change in shape or dynamics in the presence of stimuli. What is important to note is that stimuliresponsive materials need to have a field effect – the application of temperature, pressure, electric field, or light field – in order to change or elicit response from the particular stimuli. For example, in the case of polymers, we can define them at the nano to microscopic level such that we can control their swelling behavior, their contraction, their micellization, or equilibration at the interface. Types of stimuli that can be applied include temperature, pH, magnetic field, mechanical field, etc. In turn this will elicit a response on the polymer that results in a change in shape, mechanical properties, permeability, phase separation, optical and/or electrical properties.

What is 4D Printing?

4D printing allows us then to combine the design and materials in order to produce a new effect, some stimuli-response of both the material and the 3D printed object. These methods were first reported by scholars from MIT, who actually coined the term 4D printing, but what this is, simply, is stimuli-response by design. So, 3D printing is extended to “4D,” allowing one to make a variety of shapes. A good example is a shape memory nickel alloy – a material that is used for stents – good for different types of designs or cylinders that can control flow behavior. Many types of materials have been explored including metals and polymers, but in my research, I have been most interested in soft matter or polymer materials.

How are polymeric materials used in 4D Printing?

So, I mentioned our group is focused on polymeric materials. In particular we have done a lot of work on polymers at interfaces or the chemistry of interfaces and interfacial phenomena. We have done a lot of work on grafting polymers on surfaces or polymer brushes, which can be grafted using control initiators as well as the patterning of different types of polymers. Another specialty in our group is to work on poly-electrolyte multilayers. These electrostatically absorb or equilibrate polymer materials that can be used to lay flat on surfaces or take the shape of the particle or even a route toward hollow shell particles.

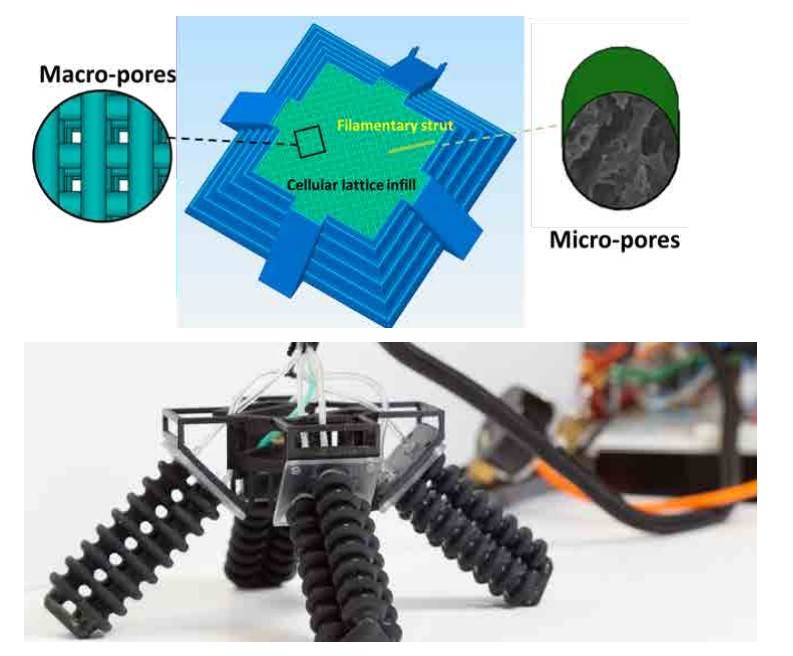

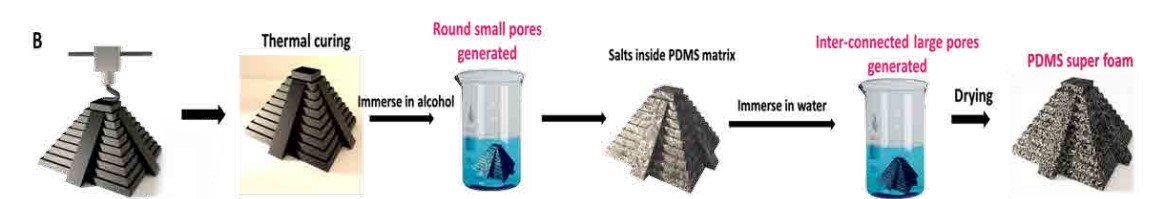

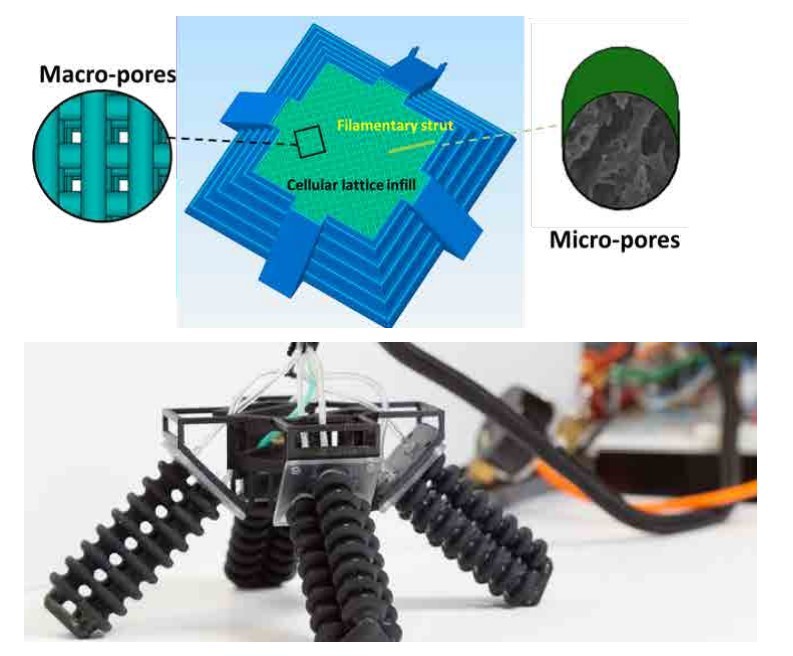

Silicon sample image 1 (above). Silicon sample image 2 (below). In this case we use a silicon material, this silicon materials were 3D printed as different objects as shown here with a formulation that shows the amount of PDS and Silicon oil added. The reason is that by varying the amount of silicon oil and salt, we are able to change the porosity.

Can you give an example?

A very simple concept is the 3D printing origami approach, using a Japaneseinspired design. The question is – how can you 3D print an object or a precursor object such that you can control the folding in the presence of stimuli? And this can be done, for example, in an origami approach by producing the creases and folds at specific locations on a flat object. The result is that you will have a hinges...you will have a distribution of hinges and folds that can be affected and stretched by heat. An advantage of 3D printing is you can actually orient the 3D printing of the material such that you can optimize the mechanical properties as well as the ability to fold.

Many cases have been reported where these architectures can be 3D printed or designed to make very complicated objects out of let's say, a printed or two dimensional design. If you are able to control the placement of those trusses, hinges and corners, with the right material and the right stimuli, when you start folding one side, you will prepare an object that basically has a fourth dimension. 4D that is an outcome of the initially 3D printed design and material as well and other examples of that 2D to 3D to 4D transition. So from flat to three dimensional to 4D, you can convert the access if you design them well, such that without using gears or without using arms, one is able to elicit movement or mechanical movement based on the design.

What is Shape Memory?

Shape memory means that the original shape can be converted back to with the appropriate stimuli. In other words, when you first form the object, if you maintain that shape, that shape is in the memory of the polymer and you can go back to the original shape as it was formed. Another type of shape memory material is used in stents or different types of biomedical applications. 4D printing the right material or composite material in this case can result in the ability to form folds or structure.

You can essentially program the shape and change them with different combinations of heat or mechanical response such that you can cycle them from one form to the other. This ability to go to various shapes simply means that you have a handle, or several handles, both mechanical and thermal to change the response. Shape memory material properties are essentially 4D printing because the property is hidden when you first print the object, but then the application of the appropriate stimuli unlocks the property that was originally present during printing.

Soft robotics sample

Do you have an example from your research?

We were interested in 3D printing different types of origami-like designs, in order to improve the movement of robotic arm methods. Using these principles will be useful for soft robotics or the ability to use 3D printing as a route towards elastomeric or thermoset elastomeric materials that can be used to activate or have movement without the use of gears, arms or different mechanical devices that are currently needed to make robot devices and objects.

In conclusion…

I hope the readers now have an appreciation of what it means to unlock a property on what we call 4D printing. The combination of design shape with the chemistry or composition of the material itself and the stimuli which you provide, whether heat, electric field, optical field, temperature or otherwise, will elicit a response. Lastly, shape memory is very much applicable to what we can 3D print in objects and metal alloys. This column is an excerpt from a webinar led by Dr. Advincula describing different types of 3D printed objects and materials that can be manipulated by applying stimuli to become “4D.” To listen to the entire webinar, go to: https://youtu.be/ crH-WpS4YyE