Keynote Speaker

Severin Krueger

Quantum dots for low noise single photon sources

Nikolai Bart, Hans-Georg Babin, Nikolai Spitzer, Peter Zajac, Elias Kersting, Meret Grell, Marcel Schmidt, Timo Kruck, Severin Krüger, Andreas Wieck, and Arne Ludwig *

Lehrstuhl für Angewandte Festkörperphysik, Ruhr-Universität Bochum, 44801, Germany * Electronic address:

A key component for photonic quantum devices is a source of high-fidelity photonic qubits, a single photon source. A promising route to create such a device employs semiconductor quantum dots (QDs) in photonic cavities.

In the past, we focused our investigations on noise processes hampering solid state emitters [1]. Decoherence and low efficiency are mainly driven by random charge rearrangements in the semiconductor environment or the QD itself. Our solution was to embed the QDs in the high purity material undoped region of a pin-[2,3] or nin-[4] diode. We successfully apply this method [5,6] to highly promising strain free local droplet etched GaAs-QDs [7,8] and discuss these QD's advantages.

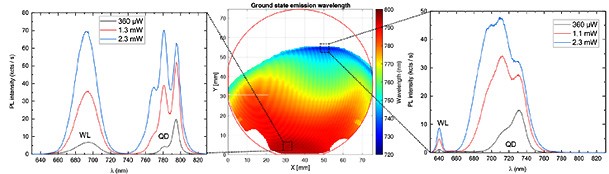

With epitaxial growth phase control of QD nucleation, we opened a new research branch. Wafer rotation stop enables material gradient growth and control over this growth phase. Newly discovered implications of this well-known method like a periodic modulation of the QD density [9] and QD-emission wavelength [10] will be presented.

Figure 1: (centre) QD photoluminescence ground state peak emission wavelength recorded on a full 3”-wafer at T = 100 K. The emission is modulated due to material gradient deposition. (left and right) Photoluminescence spectra taken at the positions indicated in the center map measured at the indicated laser power. The QDs show a clear level structure. A thin GaAs quantum well (WL) is emitting in the red spectral range. (after ref. [10])

References:

[1] AV Kuhlmann et al., Nat Phys 9 , 570 (2013).

[2] A. Ludwig et al. Journal of Crystal Growth 477 , 193 (2017).

[3] D. Najer et al., Nature 575 , 622 (2019).

[4] T. Strobel et al. Nano Lett 23 , 6574 (2023).

[5] L. Zhai et al., Nat Commun 11 , 4745 (2020).

[6] H. G. Babin et al., Nanomaterials 11 , 2703 (2021).

[7] C. Heyn, et al., Appl. Phys. Lett. 94 , 183113 (2009).

[8] M. Gurioli et al., Nat. Mater. 18 , 799 (2019).

[9] N. Bart et al., Nat Commun 13 , 1633 (2022).

[10] H.G. Babin et al., Journal of Crystal Growth 591 , 126713 (2022).