Keynote Speaker

Dr. Patrik Schmutz

AFM in controlled atmospheric environment – for realistic surface properties assessment

Dr. Patrik Schmutz, Empa-Materials Science and Technology, Laboratory for Joining Technologies and Corrosion, Dübendorf, Switzerland

Atomic Force Microscopy based techniques are extremely versatile in determining various surface properties (from topography to surface energy, electrical, magnetic, mechanical properties, aso…). In recent years, functional surfaces are also more and more desired and large effort have been dedicated to develop these smart surfaces with multiple functions. Surface reactivity and integrity is however often dependent from the environment they are exposed to. Our approach, since more than twenty years, is to make sure that the properties measured by AFM are relevant to real world applications and do not lead to inadequate developments. For this reason, we adapted AFM systems to control the environment from inert (Argon) to high humidity conditions (RH~90%). Additionally, temperature control and aggressive ions dosing for corrosion studies have been added to the surface stress factors.

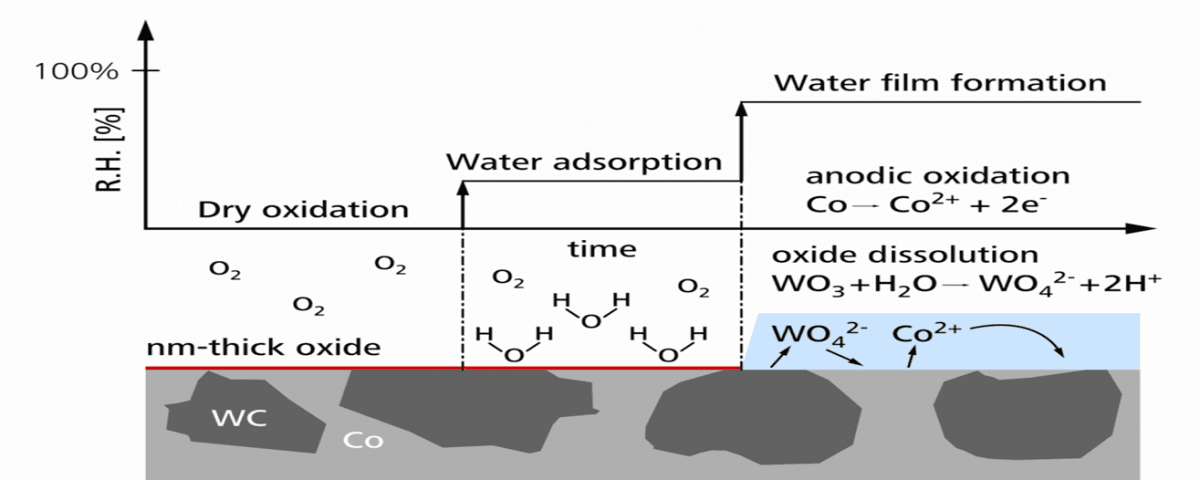

In my presentation, I will go through different examples of surface properties characterized by AFM under theses controlled or cycled humidity/temperature conditions. Fig. 1 sketches the different surface interactions that will happen on multiphase materials such as the very reactive/corrosion susceptible WC-Co composite that I will describe as one example [1]. In dry conditions, only oxidation will take place, as soon as water molecules start to adsorb (> 20% RH) an electrochemical double layer will form and above a second humidity threshold (~70% RH), mobile water molecule and ions will drastically accelerate the surface reactions. In a very early study, we could show that using the AFM based Scanning Kelvin Probe Force Microscopy (SKPFM) technique with a controlled nm-thick electrolyte layer formed, very relevant "electrochemical" information could be obtained [2]. I will describe SKPFM results for WC-Co reactivity but also discuss the technique for other surface functionalizing or oxide properties investigation [3, 4]. The overall take home message is that our studies aim at guaranteeing that the surface functionalities are really guaranteed and durable in their operation environment.

Fig.1: Varying surface interactions of heterogeneous reactive materials (e.g: WC-Co composite) as function of relative air humidity [1].

References

[1] S. Hochstrasser(-Kurz), C. Latkoczy, D. Günther, S. Virtanen, P.J. Uggowitzer, P. Schmutz, “ICP-MS, SKPFM, XPS and microcapillary investigation of the local corrosion mechanisms of WC-Co hardmetal”, Journal of the Electrochemical Society, 155(8), C415-C426 (2008)

[2] P. Schmutz, G.S. Frankel, “Characterization of AA2024-T3 by Scanning Kelvin Probe Force Microscopy”, Journal of the Electrochemical Society, 145(7), 2285-2295(1998)

[3] A. Vetushka, L. Bernard, O. Guseva,, Z. Bastl, J. Plocek, I. Tomandl, A. Fejfar, T. Baše, P. Schmutz, “Adsorption of oriented carborane dipoles on a silver surface”, Physica Status Solidi (B) Basic Research, 253 (3), 591-600 (2016)

[4] F. Evangelisti, M. Stiefel, O. Guseva, R. Partovi Nia, R. Hauert, E. Hack, L.P.H. Jeurgens, P. Schmutz, C. Cancellieri, ”Electronic and structural characterization of barrier-type amorphous aluminium oxide”, Electrochimica Acta, 224, 503-516 (2017)