Contributed Speaker

Nicolas Gonzalez

The challenge of automating and summarizing complex particle analysis of multiple AFM datasets: the case of electrochemical texturing of steel surfaces

By Mathieu Cognard1, Nicolas Gonzalez1, Christine Regent2

1 Digital Surf, Besançon (France)

2 Institut UTINAM, Université de Franche Comté, Besançon (France)

Atomic force microscopy (AFM) is a powerful tool for characterizing particle morphology, size, and shape at the nanoscale. The analysis of AFM images, however, can be time-consuming, error-prone and particularly challenging for large datasets or complex particle populations. Automated particle analysis tools are emerging as a promising solution to these challenges, enabling researchers to efficiently and accurately extract meaningful insights from AFM data.

Challenges of automating particle analysis from multiple AFM datasets

Automating particle analysis from multiple AFM datasets presents several significant challenges:

- Heterogeneity of particle samples: AFM datasets can vary widely in terms of particle morphology, size distribution and surface properties, making it difficult to develop a universal automated analysis method.

- Data complexity and scalability: samples can contain thousands of particles, presenting computational challenges for automated tools to handle such large volumes of data efficiently.

- Subjectivity and ambiguity of AFM data: AFM images often contain subtle features that can be interpreted differently by human analysts, leading to discrepancies in automated analyses.

Addressing the challenges with innovative methods

Innovative approaches to address the challenges of automating particle analysis have been developed and implemented in MountainsSPIP® analysis software:

-

Smartflows and templates allow the user to save custom workflows adapted to the nature of their sample. They can be applied to similar datasets, saving precious time.

-

Statistical documents provide a framework for quantifying particle properties, thus allowing a better understanding of particle distribution, interactions and geometric characteristics.

-

Interactive classification techniques allow particles to be grouped based on their common properties. This can be used to identify trends and correlations between particle properties and other parameters, such as material formulation or manufacturing process.

Case study: honeycomb structure characterization

As part of an ongoing PhD thesis(1) in collaboration with the UTINAM, FEMTO and ICB laboratories (Besançon, France), a stainless steel substrate exhibiting a honeycomb structure on a nanometric scale was characterized using AFM tapping mode. This nanopatterned surface was achieved electrochemically by anodically polarizing the substrate.

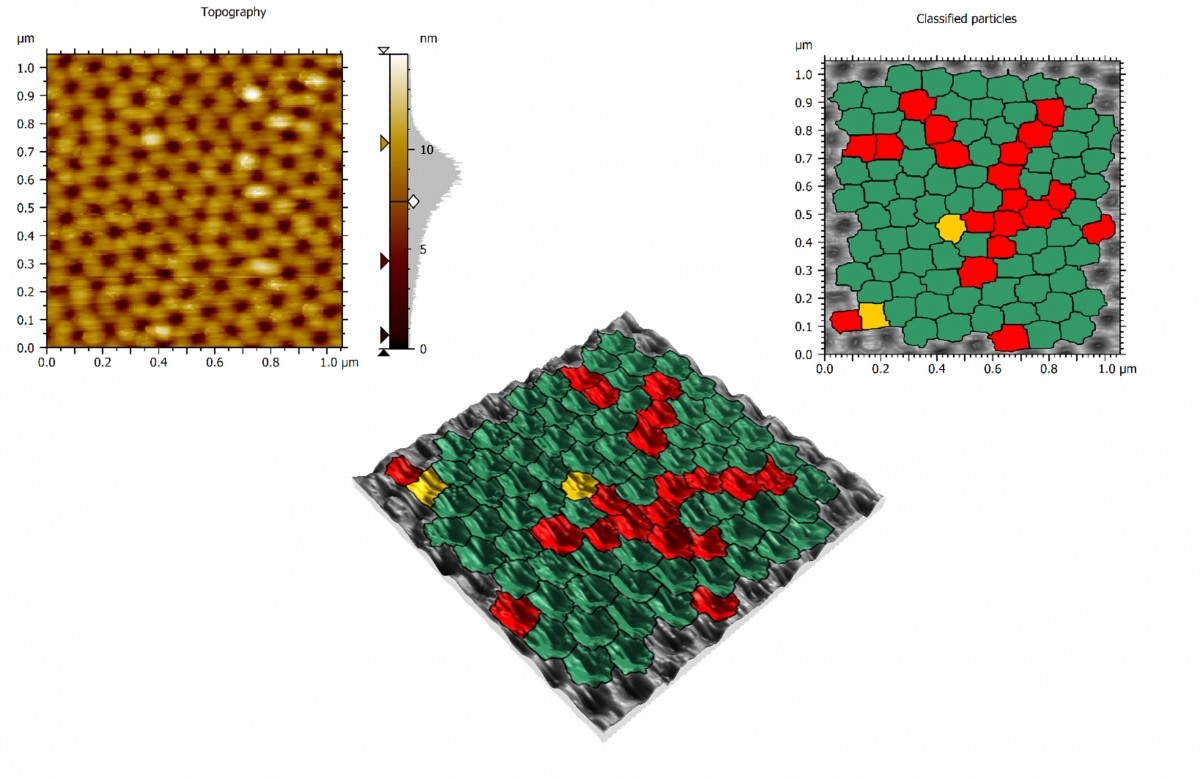

One of the purposes of this study is to understand the experimental impact of the electrochemical texturing conditions on the pattern, in order to ultimately simulate the electrochemical process. Besides cavity width & depth, which are easily assessable through image processing, other parameters are more subtle and more complex. Defects, such as size or shape differences, lead to rearrangements in the hexagonal structure. For this reason, the global surface is composed of many fold domains assembled together but different in their orientation.

Identifying the defects (shape and size), the boundaries of these domains, and their global orientation is relevant for correlating this information with the physical characteristics of the substrate (crystalline phases, grains etc.). Moreover, statistical measurements allow the determination of representative dimensions of the pattern, such as interpore distance, distance between rows of cavities, global depth, solid fraction and defect ratio.

Conclusion

Automating particle analysis from multiple AFM datasets has significant potential for scientific and industrial applications. Addressing data heterogeneity, complexity and subjectivity, automated tools revolutionize particle analysis, enabling deeper insights into particle behavior and properties. These advancements drive discoveries and innovations across various fields.

Figure 1 Top left, AFM topography of the electrochemically textured surface. Top right, particles detected and classified by validity criteria (pit depth and number of neighbors). Below, visualization of detected particles overlaid on a 3D rendering of the topography.

Keywords: AFM, particle analysis, automation, template, classification, statistics, interactive tools

References:

[1] Regent, C. Electrochemical Texturing of Steel Surfaces. Thesis in preparation, Université de Bourgogne et de Franche-Comté, 2022. https://theses.fr/s348624 (accessed 2024-07-12).