Keynote Speaker

Dr. João P. Cosas Fernandes

Interface Characterization of Sulfonated Cellulose Nanocrystal/sPEEK Nanocomposites via Photo-Induced Force Microscopy

Oussama HAMZAH¹, Maxime GONDREXON², Padraic O'REILLY³, Hakima MENDIL-JAKANI², Vincent H. MAREAU², Laurent GONON², Bruno JEAN¹, Jean-Luc PUTAUX¹, Laurent HEUX¹, Yoshiharu NISHIYAMA¹, Franck DAHLEM¹¹

Université Grenoble Alpes, CNRS, CERMAV, 601 Rue de la Chimie, Grenoble 38000 Cedex 9, France

² Université Grenoble Alpes, CEA, CNRS, IRIG-SyMMES, 38000, Grenoble, France

³ Molecular Vista, San Jose, CA, USA

Fuel cells, powered by hydrogen, offer a clean and efficient solution for electric vehicles. A key component is the proton exchange membrane (PEM), which acts as a separator and proton conductor within the fuel cell. Currently, the most advanced PEMs are made from perfluorinated sulfonic acid ionomers, but their high cost, difficulty in recycling, and performance limitations at higher temperatures and low humidity hinder widespread adoption. Sulfonated poly(ether ether ketone) (sPEEK) has emerged as a promising candidate due to its enhanced thermal stability, mechanical properties, and cost-effectiveness compared to Nafion. However, its aromatic backbone and less acidic sulfonic groups result in a less pronounced hydrophilic/hydrophilic phase separation, leading to narrower and less efficient proton transport channels. Previous attempts to enhance both conductivity and mechanical properties through modifications such as polymer blending, cross-linking, and composite formation have met with limited success, frequently compromising proton conduction. Cellulose nanocrystals (CNCs) present a promising alternative to the design of nanocomposites for PEMFC. These sustainable and abundant materials can be chemically modified to enhance the properties of PEMs, such as proton conductivity, gas barrier, mechanical strength, and durability.

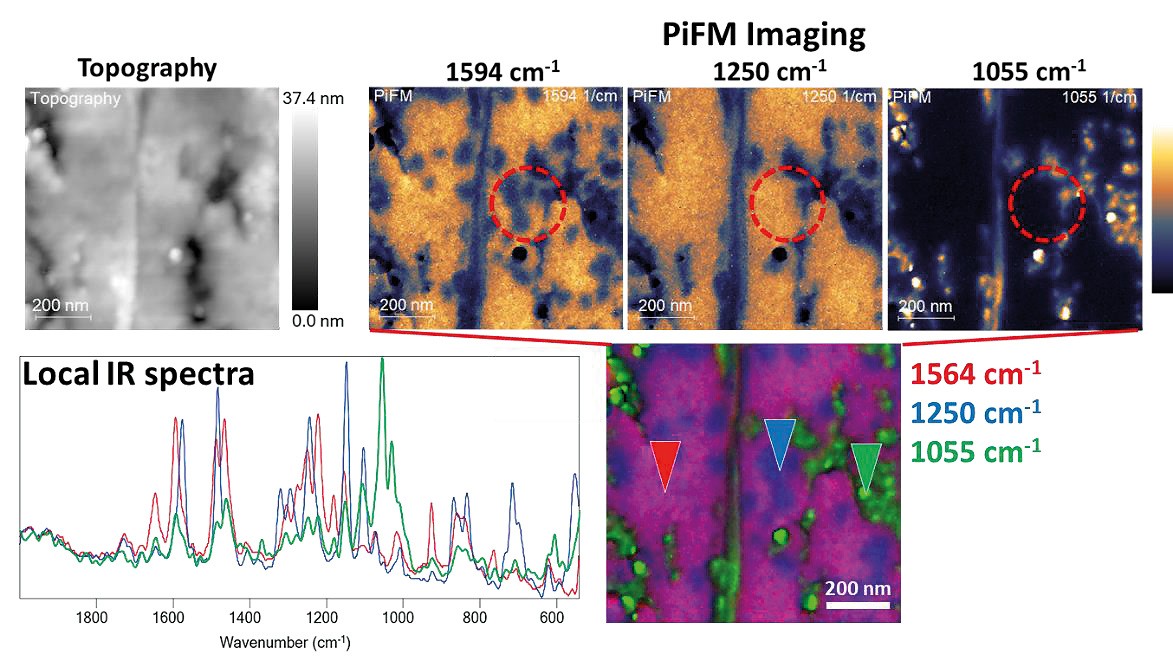

This presentation will focus on developing nanocomposite PEMs by incorporating sulfonated CNCs into a sPEEK matrix. Topographical, mechanical and chemical characterizations of the membranes were performed to show how the cellulose crystals' nature, morphology, amount and sulfonation degrees affect the matrix's intrinsic properties and the nanocomposite's final performance. For chemical analysis, a specific nano-IR technique, named infrared photo-induced force microscopy (PiFM) was applied in the cross-section of the sPEEK/CNC membranes. This provides local chemical distribution at the interfaces between the polymer matrix and the nanocrystals, allowing the investigation of the effect of chemical modifications of the CNCs on these interfaces to understand the relationship between the structure of these nanocomposite membranes and their functional properties.

Figure 1. Local chemical analysis by PiFM on the membrane's cross-section shows the distribution of each component's characteristic bands and the local IR spectra acquired in each phase.